Have you ever dreamed of owning a unique, handcrafted timepiece that reflects your personal style? Forget mass-produced clocks; the satisfying process of building your own wooden clock offers a rewarding blend of creativity and craftsmanship. This isn't a project reserved for experienced woodworkers; with a little patience and the right guidance, you can craft a beautiful, functional clock that will be a source of pride for years to come. The charm of a DIY wooden clock lies not just in its aesthetic appeal, but also in the personal connection forged through the creation process.

This detailed guide provides a comprehensive step-by-step approach, leading you through each stage of construction from selecting the wood and preparing the components to assembling the clock mechanism and finishing the piece. Whether you’re a seasoned DIY enthusiast or a complete beginner, get ready to embark on this fulfilling project, and let's begin building your very own personalized wooden clock!

Preparation and Safety Guidelines

- Scroll saw

- Spray adhesive

- Sanding strip

- Drill

- Chisel

- Table saw

- Dado stack

- Dial caliper

- Sandpaper

- Rotary tool

- Arbor press

- Dead blow hammer

- Clamps

- Shellac

- Disc sander

- General finishes and dur

- Always wear safety glasses to protect your eyes from flying wood chips and debris.

- Use caution when operating power tools. Ensure the workpiece is securely clamped before cutting or sanding.

- Handle sharp tools with care. Keep them out of reach of children and store them properly after use.

Step-by-Step Instructions

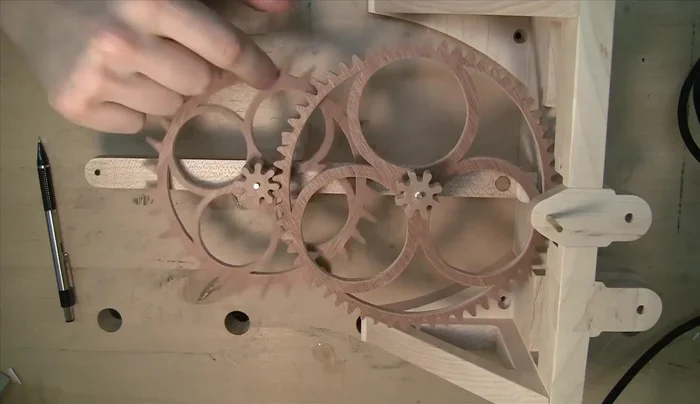

Gear Preparation

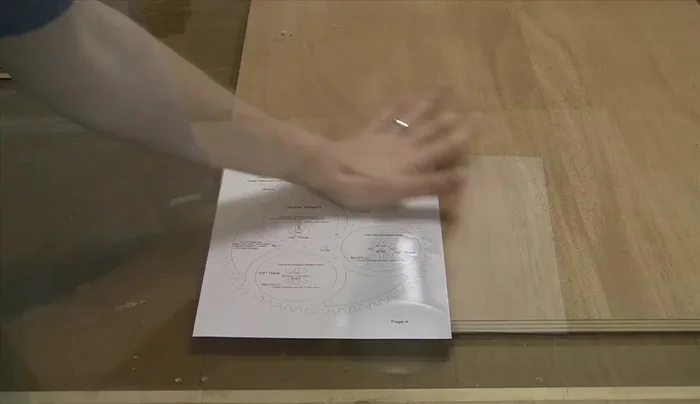

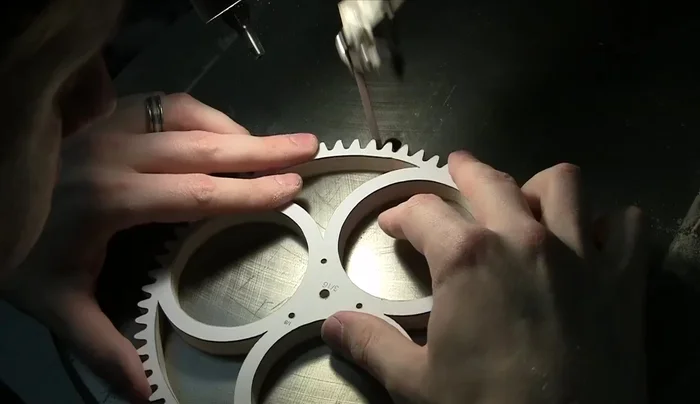

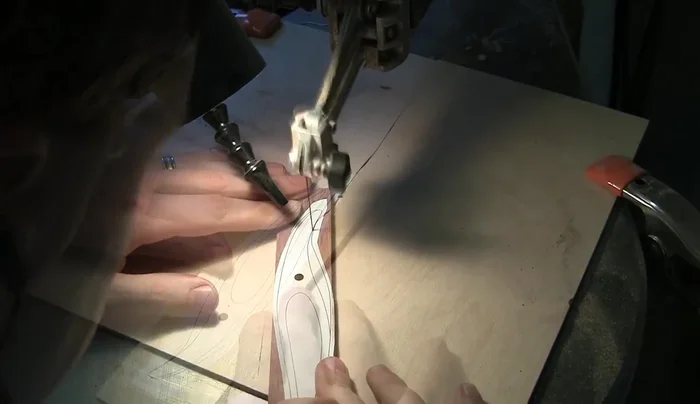

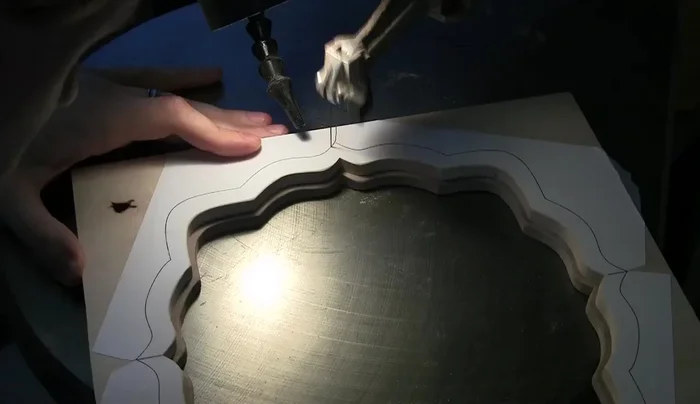

- Cut the gears from high-quality plywood using a scroll saw with a fine blade. A pre-drilled hole helps with starting the cut.

- Clean up the gear teeth using a sanding strip in the scroll saw. Remove the paper template.

- Sand the escape wheel tips to ensure they are crisp and concentric by mounting the wheel on a shaft.

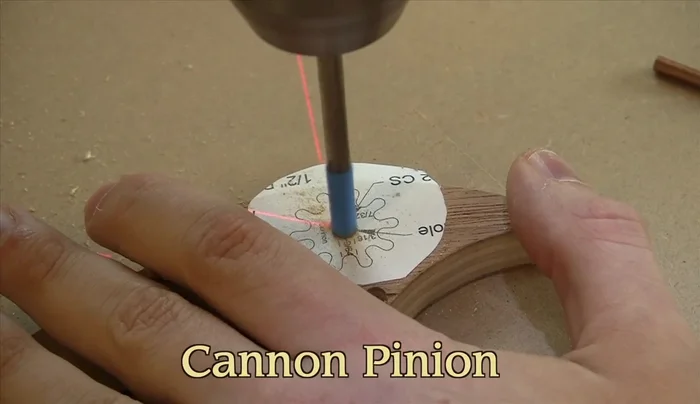

- Drill holes and countersinks for the cannon pinion, ensuring concentricity.

Gear Preparation Frame Construction

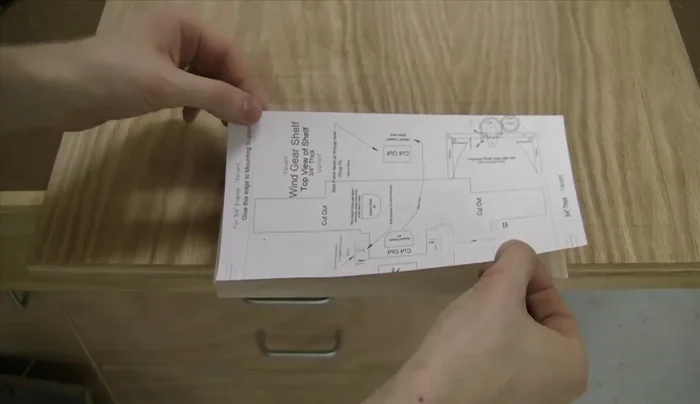

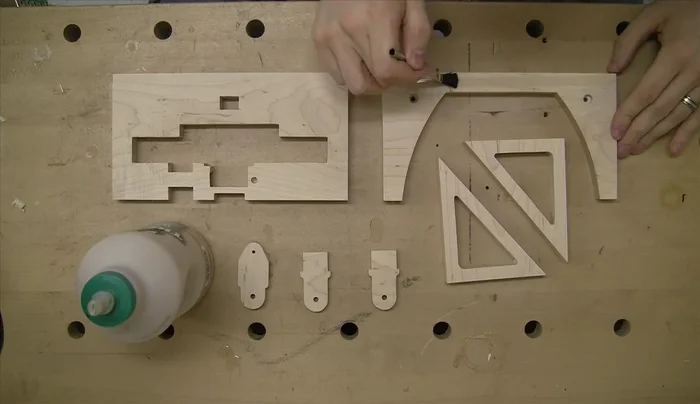

- Cut the frame pieces from solid maple using the scroll saw and templates.

- Create notches for the drive gear using a chisel.

- Use a dado stack at the table saw to create the wine shaft support.

Frame Construction Sub-Assembly Construction

- Glue and assemble the drive gear, pulley, and click gear assembly. Use a drill bit to hold the parts in position while the glue dries.

- Assemble the intermediate wheel, spacer, and pinion; the third wheel, spacer, and pinion; and the escape wheel, spacer, and pinion assemblies. Insert brass tubes using an arbor press.

Sub-Assembly Construction Frame Assembly

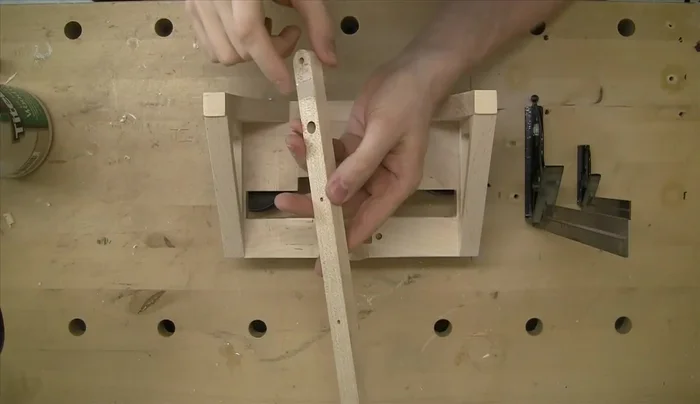

- Glue and clamp the frame pieces together. Add screws for extra support.

- Glue the rear vertical frame to the main frame.

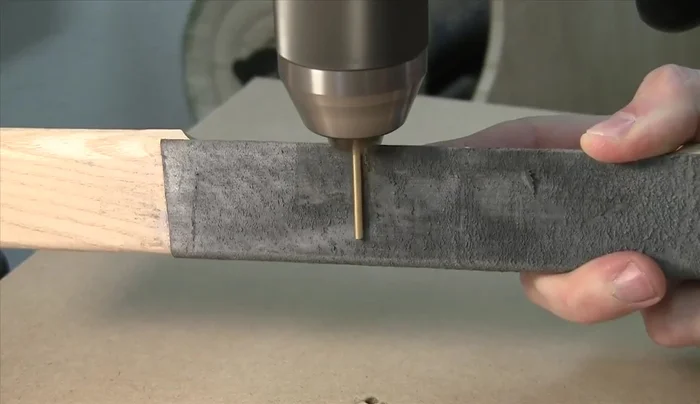

- Polish the brass shafts before pressing them into the rear vertical frame using an arbor press and dead blow hammer.

Frame Assembly Gear Fine-Tuning

- Fine-tune the gears by manually spinning them and using a rotary tool to relieve material where the gears bind.

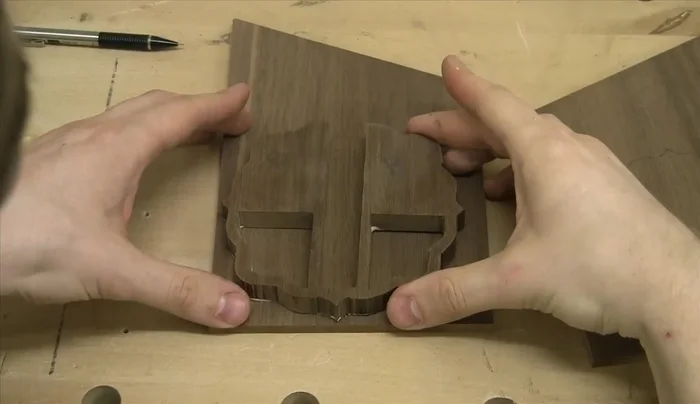

Gear Fine-Tuning Pendulum Bob Creation

- Make the pendulum bob from three pieces of walnut, adding lead shot for weight.

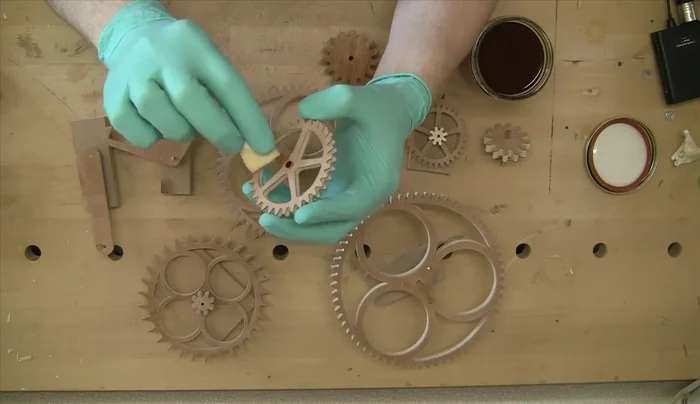

Pendulum Bob Creation Finishing and Assembly

- Apply shellac to the gears, avoiding the teeth.

- Assemble the clock, add a weight, and adjust the pendulum for optimal performance.

Finishing and Assembly Hand and Face Creation

- Make the clock hands from purple heart and canary wood, shaping them with a disc sander and rotary tool.

- Cut the clock face from a maple and walnut sandwich.

Hand and Face Creation Weight Creation

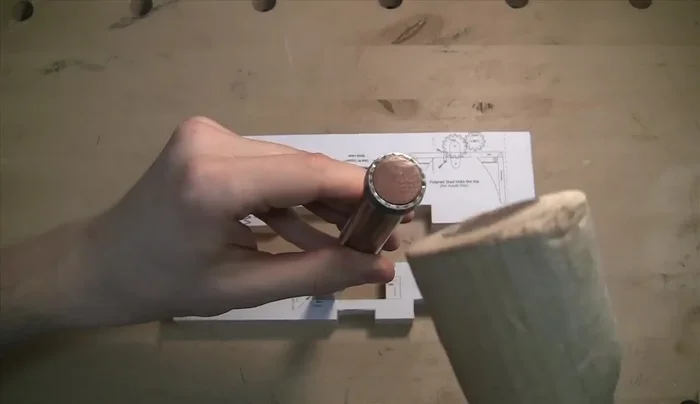

- Make the clock weight from a steel tube filled with lead shot and capped with walnut.

Weight Creation Final Finishing and Hanging

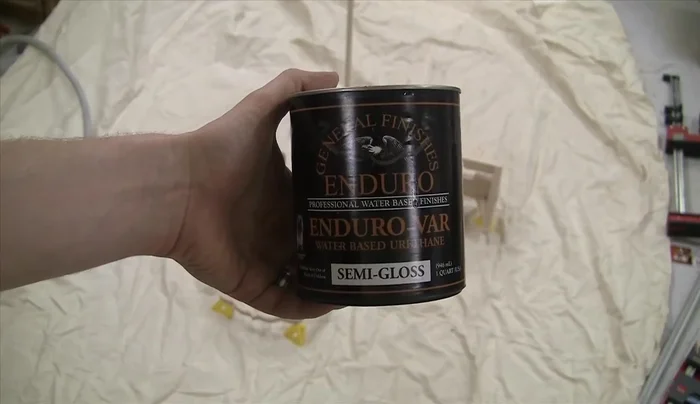

- Finish the remaining clock parts with a high-quality water-based finish.

- Hang the clock.

Final Finishing and Hanging

Read more: Build a Stunning Black Walnut Coaster Set: The Ultimate Furniture Protector

Tips

- Use high-quality plywood for stability.

- Ensure good glue contact when assembling the frame.

- Adjust the pendulum for optimal performance after assembly.