Tired of exorbitant prices for queen-size bed frames? Do you dream of a stylish, supportive bed without breaking the bank? Then you've come to the right place! This guide will walk you through building your own queen-size bed frame – a project that's surprisingly affordable, remarkably sturdy, and incredibly easy to assemble, even for beginners. Forget flimsy, mass-produced frames that wobble and creak; you'll be crafting a custom piece that perfectly fits your style and budget.

This DIY project requires minimal tools and readily available materials, making it a perfect weekend project. We’ll cover everything from choosing the right wood to securing each joint, ensuring a robust and long-lasting frame. Ready to transform your bedroom and save money at the same time? Let's dive into the step-by-step instructions and build your dream bed!

Preparation and Safety Guidelines

- 2x4s

- 2x6s

- Wood Glue

- Clamps

- Drill

- Drill bits

- T-nuts

- Bolts (3/8 inch)

- Wrench

- Hammer

- Sandpaper

- Always use sturdy lumber and appropriate fasteners (screws, not nails) to ensure structural integrity. Weak materials can lead to collapse.

- Ensure all screws are fully tightened to prevent movement or wobbles. Regularly check the frame for any loosening over time.

- Before assembling, carefully read all instructions and pre-drill pilot holes whenever screwing into wood to prevent splitting.

Step-by-Step Instructions

Cut and Prepare Lumber

- Cut two 2x6 boards to 84 inches and two 2x4s to 74 inches.

- Cut four 2x4 legs to 11 inches each.

- Cut two 5-foot header and footer boards.

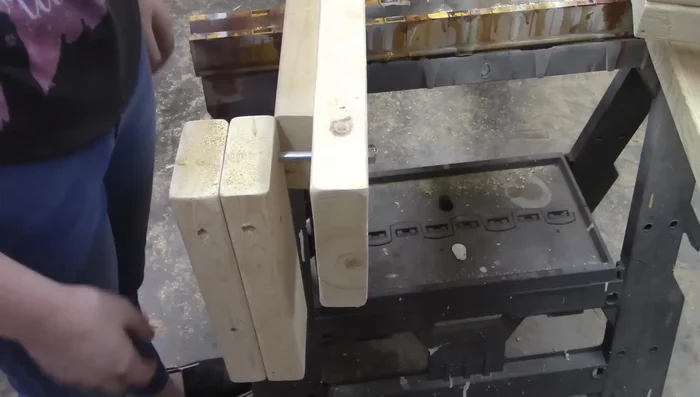

Cut and Prepare Lumber Assemble Rails

- Center and glue the 74-inch 2x4s onto the 84-inch 2x6s to create the left and right rails.

Assemble Rails Sand Rails and Legs

- Sand the rails to remove splinters and imperfections.

- Sand the legs.

- Sand the header and footer boards.

Sand Rails and Legs Prepare for Leg Attachment

- Drill pilot holes in the rails for the leg bolts. Use each leg as a template for accurate hole placement.

- Drill slightly larger holes for the T-nuts in the rails.

- Drill holes in the header and footer boards for bolts to attach to the legs.

Prepare for Leg Attachment Install T-nuts and Attach Legs

- Hammer the T-nuts into the larger holes.

- Attach the legs to the rails using three bolts per leg and the T-nuts.

Install T-nuts and Attach Legs Add Support Structure

- Attach 2x4 Raptor hangers to the header and footer boards.

- Cut the center support rail to fit within the Raptor hangers.

Add Support Structure Prepare and Install Slats

- Cut the support slats (8-foot 2x4s) into 5-foot lengths.

- Create the 'teeth' (short 2x4 pieces) to keep the slats in place. Cut 2x4 scraps to 3.75 inches in length.

- Glue the teeth to the rails, leaving space between each tooth for the slats.

Prepare and Install Slats Final Assembly and Finishing Touches

- Sand all the pieces after gluing.

- Attach the center leg (11-inch 2x4) using T-nuts and bolts.

Final Assembly and Finishing Touches Complete and Enjoy!

- Place the mattress and enjoy your new bed frame!

Complete and Enjoy!

Read more: Build a Stunning Black Walnut Coaster Set: The Ultimate Furniture Protector

Tips

- Using glue reduces the number of screws needed, making assembly easier and cheaper.

- T-nuts prevent losing fasteners during disassembly.

- Working with a partner speeds up the process.

- The design allows for easy disassembly for transport, requiring only the removal of four bolts.