Have you ever admired the intricate detail of miniature wheels on model cars, dollhouses, or even intricate clockwork mechanisms? Creating these tiny marvels can be a surprisingly rewarding experience, offering a satisfying blend of precision and creativity. Building your own spoke wheels, while seemingly daunting, is entirely achievable with the right tools and a methodical approach. Forget expensive pre-made miniatures; mastering the art of DIY miniature wheel construction unlocks a world of customization and allows you to perfectly match your wheels to your project’s unique aesthetic.

This detailed guide provides a comprehensive step-by-step process for crafting flawlessly symmetrical and durable miniature spoke wheels. From selecting the appropriate materials to expertly tensioning the spokes, we will walk you through each stage, ensuring you produce miniature wheels of exceptional quality. Let's get started and unlock the secrets to creating these charming miniature components!

Preparation and Safety Guidelines

- 20 mil hole saw

- drill lathe

- 3 mil drill bit

- bamboo skewers

- block of wood

- clamp

- 6 mil hole

- 6 mil dowel

- 12 mil wood

- forstner bit

- 54 mil hole saw

- compass

- Use appropriate safety glasses and gloves throughout the entire process to protect your eyes and hands from sharp materials and potential injuries.

- Work in a well-ventilated area. Some glues and paints used in this project release fumes that can be harmful.

- Always supervise children if they are participating in any part of this project to prevent accidental ingestion or injury from small parts.

Step-by-Step Instructions

Create the Axle Hub

- Create the axle hub using a 20 mil hole saw, aiming for a 16 mil wide axle hub for a 2 inch (50 mil) wheel.

- Clean up the axle hubs using a drill lathe. Be prepared for cracks and discard damaged pieces; using recycled timber requires this.

Create the Axle Hub Prepare the Spoke Jig

- Prepare a jig for creating spoke holes. Use a block of wood with a 6 mil hole for a 6 mil dowel (axle hole size). Draw lines at 45 degrees for eight spokes.

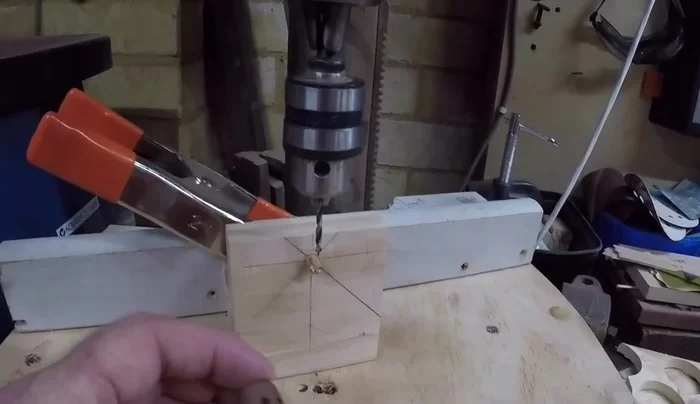

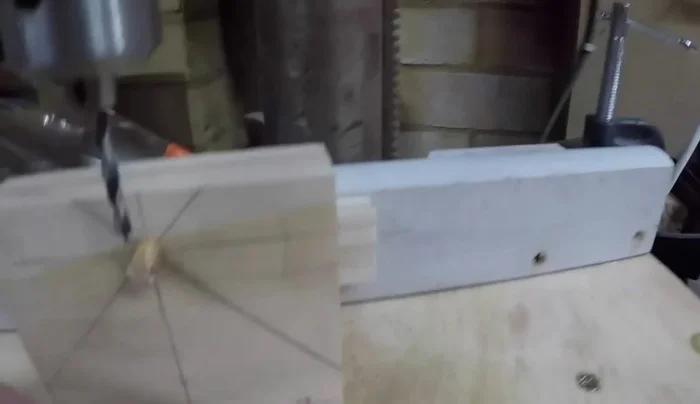

Prepare the Spoke Jig Drill Spoke Holes

- Drill spoke holes using the jig, ensuring alignment with the axle hub. Keep the jig attached to a fence for stability. Discard any pieces where the drill bit follows the grain.

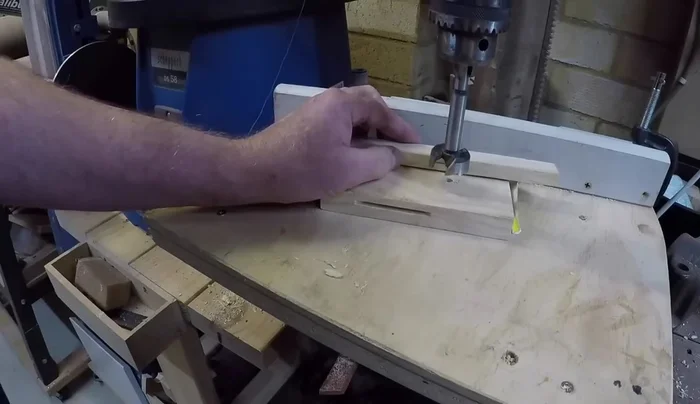

Drill Spoke Holes Create the Wheel Rim

- Create the wheel rim. Start with a 12 mil piece of wood. Drill a fine hole through where the wheel spokes will be.

- Using a forstner bit, create a recess halfway through the 12 mil wood for the inner diameter of the rim. This corresponds to the inside diameter where the spokes will sit.

- Use a 54 mil hole saw to create the 50 mil external diameter of the wheel.

- Drill a 32 mil hole through one side of the wheel rim (explained later).

Create the Wheel Rim Prepare the Assembly Jig

- Create a jig for aligning the hub to the outer rim. Use a piece of 12 mil scrap wood with a circle drawn using a compass set to a 16 mil radius.

- Use a 16 mil forstner bit to drill a hole about two-thirds of the way through the jig. Ensure the center circle is concentric with the outer circle.

Prepare the Assembly Jig Assemble the Wheel

- Assemble the wheel by inserting the spokes and attaching the rim to the hub using the jig for precise alignment.

Assemble the Wheel

Read more: Build a Stunning Black Walnut Coaster Set: The Ultimate Furniture Protector

Tips

- Be prepared to discard many pieces due to cracking or grain issues when using recycled timber.

- Use a jig for accurate spoke hole placement and hub-rim alignment.

- Ensure the center circle of your jig is perfectly concentric with the outer circle for proper alignment.