Mid-century modern design, with its clean lines and minimalist aesthetic, continues to captivate homeowners. Adding a touch of this iconic style to your living space can be surprisingly easy and rewarding, especially with a simple DIY project. These stylish bookends, crafted from readily available wood, offer a perfect opportunity to inject some MCM charm into your home while honing your woodworking skills. The understated elegance of these bookends makes them a perfect addition to any bookshelf, adding a subtle yet sophisticated touch to your décor.

This project is ideal for beginners, requiring only basic tools and a little patience. No prior woodworking experience is necessary to create these beautiful and functional bookends. Ready to get started and bring a piece of mid-century modern design into your home? Let's dive into the step-by-step instructions below.

Preparation and Safety Guidelines

- Wood

- Jig

- Dremel with cutoff wheel

- Bench grinder

- 220 grit sandpaper

- Mother's polish

- Buffing wheel

- 10mm socket

- Bench vise

- Block of wood

- Wood glue

- Super glue

- Water-based polyurethane

- Steel wool

- Always wear safety glasses to protect your eyes from flying wood chips and debris.

- Use clamps to secure your wood pieces firmly during gluing and while the glue dries to prevent warping or shifting.

- Ensure proper ventilation when using wood finishes and paints; always follow the manufacturer's safety instructions.

Step-by-Step Instructions

Prepare the Wood

- Create a jig to help cut the wood at the desired angle.

- Cut the two main wood shapes using the jig.

Prepare the Wood Prepare the Metal Foot

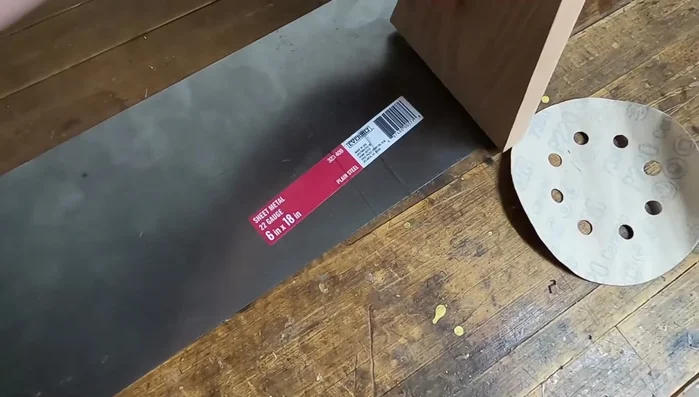

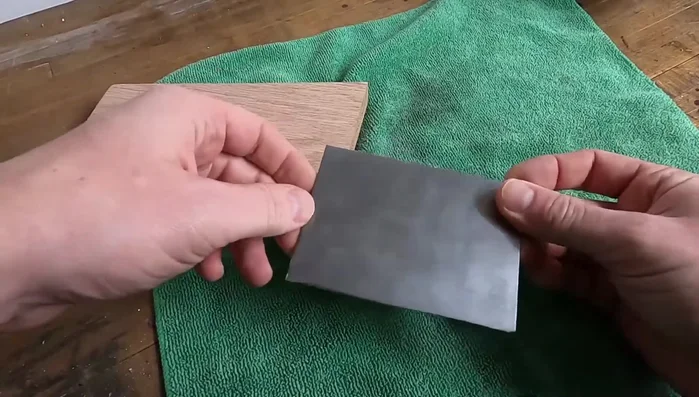

- Cut the steel piece to size using a Dremel and cutoff wheel.

- Clean up the steel edges using a bench grinder.

- Radius the edges of the steel using a bench grinder and sandpaper for smoothness.

- Polish the steel using Mother's polish and a buffing wheel.

Prepare the Metal Foot Attach the Metal Foot to the Wood

- Route out a slot in the bottom of the wood pieces to accommodate the metal foot.

- Insert the steel foot into the wood slot, mark the bend point, and bend the metal to a 90-degree angle using a bench vise and a block of wood.

- Cut a spline to create a tight interference fit for attaching the metal foot to the wood.

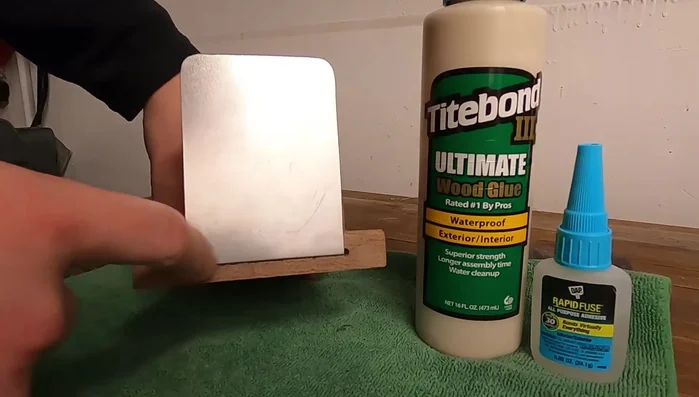

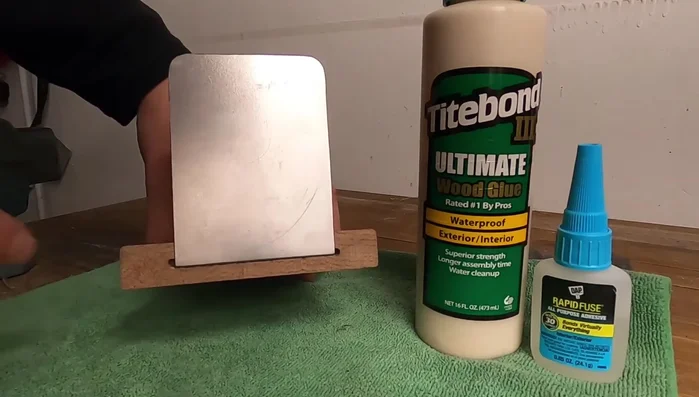

- Apply wood glue and super glue to secure the metal foot to the wood.

Attach the Metal Foot to the Wood Finish the Bookends

- Apply polyurethane finish to the wood and let it dry.

- Sand the finish with steel wool for a smooth, low-sheen finish.

- Assemble the bookend by inserting the metal foot into its slot and ensuring a tight fit with the glue.

Finish the Bookends

Read more: Build a Stunning Black Walnut Coaster Set: The Ultimate Furniture Protector

Tips

- Get it right the first time to minimize cleanup work.

- Use a block of wood to bend the steel for an even, 90-degree angle.

- When bending sheet metal, push further than the desired point to account for springback.